Battery cells are connected in a general battery to form a battery module irrespective of size and capacity. These battery cells are interconnected to supply households or businesses with stored solar energy for hours. The connection of several battery modules together scales the capacity of the battery.

Since there are different applications their power requirement is also different. To cater to these requirements multiple battery compositions with varied characteristics are available. At HIS we generally rely on Lithium Iron Phosphate, known as LiFePO4 or LFP batteries. For most applications, LFP batteries are used as they are familiar in mobile phones, notebooks, electric cars, and so on.

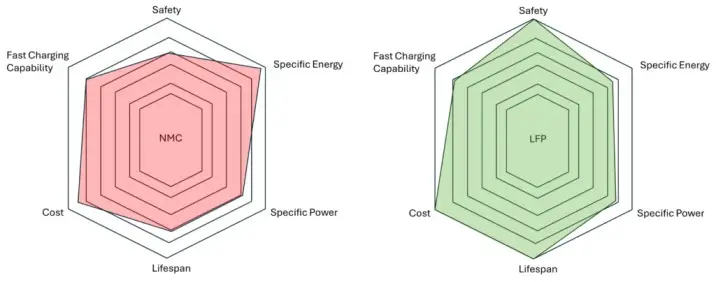

However, within the broad category of lithium-ion batteries, the performance of batteries varies due to particularly used cathode material. Lithium-ion batteries typically consist of a conductive substrate, often aluminum foil coated with an active material to facilitate both lithium ions and electric current storage. The most common chemistries for these battery cells include lithium-nickel-cobalt-manganese (NMC), lithium-nickel-cobalt-aluminum oxide (NCA), and lithium-iron-phosphate (LFP).

Advantages of Using LFP Battery

Safety

Secure battery solutions are given the highest priority and that’s why we do not compromise safety features in our battery solutions. Our battery solutions can withstand excessive temperature, current, voltage, or short circuits as they have electrical/mechanical protective circuits. When compared with other LIB cell technologies, LFP technology provides more safety. In the case of a short circuit or hit by an object that may penetrate inside the battery cells, most batteries start burning or explode. Batteries that remain stable in the highly likely above stated conditions are considered reliable to be used in BESS. Many of the currently available batteries in the market cannot pass this test and, therefore, are not suitable for use in battery storage systems.

However in other batteries unstable chemical and thermal cathode material (e.g. NMC ) can trigger exothermic chemical reactions within a cell. This exothermic reaction is a result of excessive heat generation due to overcharging, internal or external short circuits, contamination during production, strong heat exposure or mechanical damage. The internal temperature of a cell rises when the release of heat energy increases the reaction speed of a cell’s chemistry. If a certain temperature threshold is surpassed, the self-accelerating reaction becomes uncontrollable, leading to thermal runaway. This can cause the battery cell to catch fire or even explode. The situation is further complicated by the release of oxygen from the cathode material, making the fire extremely difficult to extinguish.

Unlike other batteries, LiFePO4 batteries never experience thermal instability. This eliminates the risk of overheating and potential fires. With a stable temperature profile under extreme conditions, LFP batteries have stable thermal behavior (up to 300°C) and are not self-igniting (due to overcharging). On the other hand, in NMC or NCA cells a short circuit can produce a quite high temperature of over 700°C which may melt the separator and spread to other cells. This results in a fire that cannot be extinguished even underwater because oxygen for combustion is already contained in a battery material. That’s why the LFP battery is a preferred choice to be used in battery energy storage systems.

Longevity & Cycle Resistance

Battery cells when exposed to chemical, thermal and mechanical changes their original capacity loses a little with every charge and discharge (operating cycle). This simply means it stores less and less energy over time. You may also know this from your mobile phone as after 2 years even the fully charged battery lasts only half a day.

Due to the slightly lower cell voltage of 3.2V, LFP cells have a somewhat lower energy density compared to NMC cells. However, this initial drawback is quickly outweighed by their cycle stability, which can be up to ten times greater, offering significant long-term advantages. With every operating cycle NMC cells age and after 2500-3000 cycles, they are left with 80 percent of their initial capacity. As a result, the slightly higher upfront costs of using lithium iron phosphate are offset over time.

Since the battery demand is higher in mobile apps, LFP batteries deliver a longer service life in portable and mobile devices. Due to the longer lifespan of battery storage systems using LFP technology in stationary applications, the relative storage costs (Levelized Cost of Storage, or LCOS) can be decreased by as much as 50% over their lifetime when compared to NMC batteries.

Proven Technology

The LFP technology used in HIS-Energy solutions guarantees delivery of specific performance even if the battery is moving to the end of its lifecycle. Besides this, the memory effect of LFP cells makes it superior to other LIBs. When a battery is partially discharged frequently, it results in a loss of capacity in a battery which is also known as the memory effect. The battery “remembers” the energy demands and, over time, adjusts to supply only the amount of energy needed for previous discharge cycles, rather than the full original capacity.

Lithium Iron Phosphate batteries have high power density when compared to other LIBs. This allows the LFP battery to charge and discharge currents along with an increased pulse load capacity. With higher currents, LFP cells can be charged quickly but constant rapid charging shortens the lifespan of this battery. This effect of rapid charging occurs to a small extent in LFP cells. With smart system design, cost-effective solutions for stationary applications that strike the perfect balance between charging and discharging rates, cycle stability, and lifespan can be created. This approach helps reduce the overall Levelized Cost of Storage (LCOS) throughout the system’s lifetime, ensuring both efficiency and long-term value.

Eco-Friendly Batteries

LFP is unique among cathode materials because its chemical composition naturally occurs as a mineral and does not require any additional raw materials for the chemical reactions to take place. That is why our battery solutions do not have cobalt or nickel as these are toxic heavy metals with an effect on the environment. In LFP cells, all of the lithium is utilized for the chemical reaction. In contrast, other lithium-ion batteries only use about 50-60% of the lithium, as using more can cause instability in the layer structure, or the remaining lithium becomes part of the cathode’s crystalline structure. This efficiency reduces the amount of lithium needed per kWh from around 140 grams (in NMC/NCA batteries) to approximately 80 grams in LFP cells.

LFP Batteries - The Safest Technology for Applications

Lithium Iron Phosphate Battery is reliable, safe and robust as compared to traditional lithium-ion batteries. LFP battery storage systems provide exceptional long-term benefits, with up to 10 times more charge cycles compared to LCO and NMC batteries, and a low total cost of ownership (TCO). They offer reliable performance with minimal maintenance, making them a solid investment that ensures both safety and long-lasting functionality.

LFP batteries are preferred for applications due to their cycle durability, lower internal resistance, higher efficiency and wide operating temperature range. For the fastest and safest all-in-one battery solutions, HIS-Energy offers top-tier options with their 215KW and 233KW premium batteries. Integrated with a battery management system (BMS), our energy solutions are designed for your commercial and industrial applications.